Key Capabilities

Robadair Ltd. has a management team and staff that have years of engineering and design background, product development and manufacturing skills. Couple this with modern facilities and technology and we have a winning team.

Robadair Ltd. has the ability to and will take on any contract no matter how large or small. In order to maintain the leading edge in high-tech manufacturing and machining, Robadair Ltd. provides both in-house and specific job training for our greatest asset, our employees. This in turn offers our customers improved product design, a higher level of quality, and lowers the cost of manufacturing.

Robadair Ltd. offers a suite of solutions and capabilities that can fulfill the needs of any potential customer searching for a precision metal manufacturing partnership.

Sales:

A knowledgeable staff waiting to assist with any problems or questions.

Machine Shop (CNC & Conventional):

Licenced Professionals.

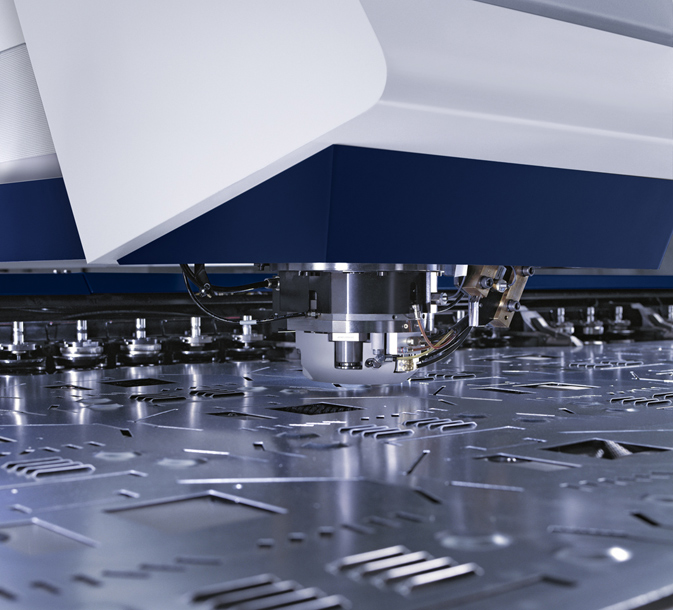

Laser Cutting

Up to and including; .375″ Aluminum

.625″ Stainless Steel

.800″ Mild Steel

Punching (CNC & Conventional):

Up to and including; .250″ Aluminum

.125″ Stainless Steel

.125″ Mild Steel

Forming (CNC & Conventional)

125 Ton Up to and including 10′ lengths.

Welding:

CWB Certified welders. Specializing in TIG and MIG Aluminum, Mild and Stainless Steels.

Iriditing:

Coatings for aluminum to protect from corrosion and for paint adherence.

Coatings for aluminum to protect from corrosion and for paint adherence.

Finishing:

Grinding and buffing (welds), manual deburring (edges), sanding, polishing. Automated timesaver unit ensures precision and efficiency.

Assembly:

A mechanical assembly team with over 30 years experience.

Paint Shop:

Automated Wet and Powder Paint lines

for smooth and texture finishes.

Inspection:

Operational & Final.

Shipping:

Using our own trucks to facilitate pick-up and deliveries

to minimize damage from product handling.